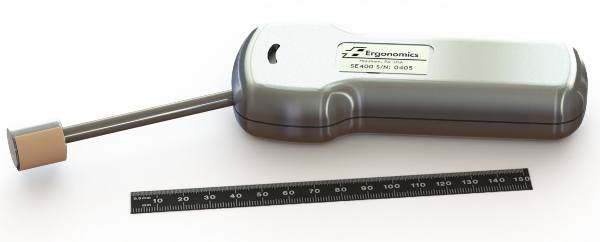

Ergonomics Sharp Edge Tester Kit – Model SE400K1

The Sharp Edge Tester Kit is used for determining the sharpness of edges of electrical equipment and other consumer products. This kit meets Underwriters Laboratories (UL) standard 1439 and Society of Manufacturing Engineers requirements. It is made of a durable metal (not plastic) housing which fits ergonomically into the palm of the hand. Industry-leading features include a compact arm, shielded ball bearings to reduce friction and a spring which meets the latest UL force requirement. All moving mechanisms are protected against dirt and breakage.

The SE400K1 is also used for compliance with US Federal regulations for consumer products. It also meets requirements for Canadian regulations. The US Federal regulation is Title 16, Volume 2, Chapter 11, Part 1500. The arm pressure can be adjusted over a wide range to accommodate all regulations and custom requirements.

This Model SE400K1 consists of the Sharp Edge Tester instrument, fifty four (54) Tape Caps, and a durable, protective carrying case (Shown below). The tape caps are constructed to meet the latest revised UL standards. They consist of three (3) pre-assembled tapes on a plastic cap. The cap slips onto the SE400K mandrel for testing. The tape caps are constructed using three (3) layers: one layer of black foam tape, one layer of white tape; and one layer of skived Teflon® tape. The caps are interchangeable with sharp edge testers made by other manufacturers.

The Tape cap is the most efficient way for the inspector to easily and quickly conduct multiple tests. Each time a test is performed with the tape cap, it can be removed, identified and replaced within seconds thus providing more tests in less time to facilitate inspection reports.

A rugged protective carrying case is provided to prevent this equipment from damage in the field or in the laboratory. This case also will extend the use of this high quality product.

Protective Carrying Case

This latest SE400K1 model replaces previous versions SE100, SE200, and SE300.