Impactors for Hammer Test

Read More

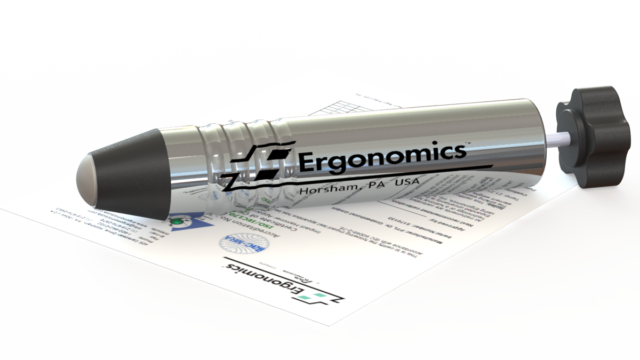

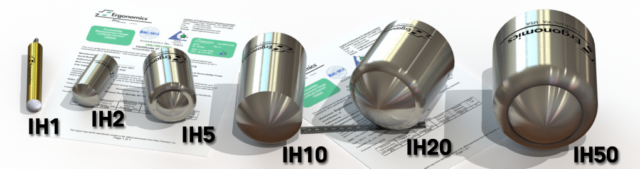

Ergonomics design, fabricates, and calibrates an array of impactors that comply with the Hammer Tests required in IEC 60068-2-75:2014. Below is our Model IH1, which complies with Figure A.1 of IEC 60068- 2-75:2014. This impactor is designed and fabricated in our tool and design shop located in the same facilities as our ISO 17025:2107 calibration