Single Energy Impact Hammers

SIH10 Series, Model SIH200

IEC Standards: 60068-2-75, 60065, 60335, 60598, 60601, 61010

SIH10 Series (0.2 to 1.0 Joule range):

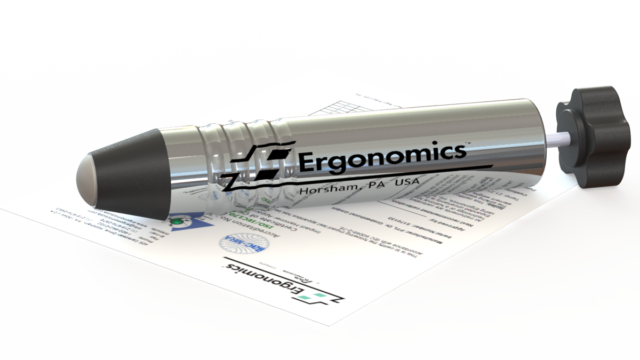

The SIH10 series Impact Hammer is designed to perform impact tests for product durability. This Impact Hammer simulates mechanical impact to electronic products and electrical appliances for one (1) specific energy level, ranging in values from 0.20 Joules to 1.0 Joules.

A release mechanism assures a release force that is standardized at 10 N. The spring is easily released from a lock mechanism by pressing the cone-shaped polyamide tip of the impact hammer against the product under testing.

SIH10 Series Standard Product Specifications

1. The SIH10 series impact hammer releases energy at any of the following energy levels: 0.20 Joules, 0.35 Joules, 0.50 Joules, 0.70 Joules, and 1.00 Joules.

2. The body, including release mechanism and striking element, has a mass of 1250 grams and an outside diameter of 50 mm

3. The spherical striking element includes a cocking knob and hammer head. The material is steel, has a radius of 10 mm, a total mass of 250 grams, and a total apparatus mass of 1.57 kilograms

4. The hammer includes a release cone of 60 grams mass and a helical compression spring of 9 grams mass

Model SIH200 (2.0 Joule):

This Impact Hammer SIH200 simulates mechanical impact to electronic products and electrical appliances for one (1) specific energy level – 2.00 Joules (or Nm). This model is the same as the SIH10 except for the striking element size, material and weight. According to IEC60068-2-75 the striking element tip must be made of steel, with a special 25 mm radius and it must weigh 500 grams.

The SIH200 also has an optional Hammer Loader Activation Device to assist in loading the hammer with minimal effort. Please see the picture below for this item, Model SIH200 Loader.

The SIH10 series and the SIH200 meet the testing requirements of industry standards such as IEC 60068-2-75:2014, as well as IEC 60065, 60335, 60598, 60601 and 61010.

A release mechanism assures a release force that is standardized at 10 N. The spring is easily released from a lock mechanism by pressing the cone-shaped polyamide tip of the impact hammer against the product under testing.

Ergonomics ensures these hammers are designed and built to work safely and easily in laboratory and product testing environments. We can also provide an ISO 17025 ILAC and A2LA accredited calibration certificate with this equipment.

Our ISO 17025 accredited laboratory is equipped to supply the certification documentation required to adhere to the strict standards set forward by the IEC and other regulating agencies.